Robotics and Autonomous Systems Engineering

Engineering Robotics for Real‑World Impact

Robotics is no longer experimental. Today’s industrial, commercial, and service robots must operate reliably in complex environments, meet strict safety and compliance standards, and scale economically. Powersoft19 partners with B2B companies and OEMs worldwide to engineer robotic and autonomous systems that are production‑ready, certifiable, and built for long‑term evolution.

We are an engineering‑led robotics partner, supporting clients across the full product lifecycle from early concept validation to certified, market‑ready robotic products, and ongoing enhancements.

Robotics Domains We Engineer

Our teams work across multiple robotics categories, allowing us to adapt proven engineering principles to different applications and operating conditions.

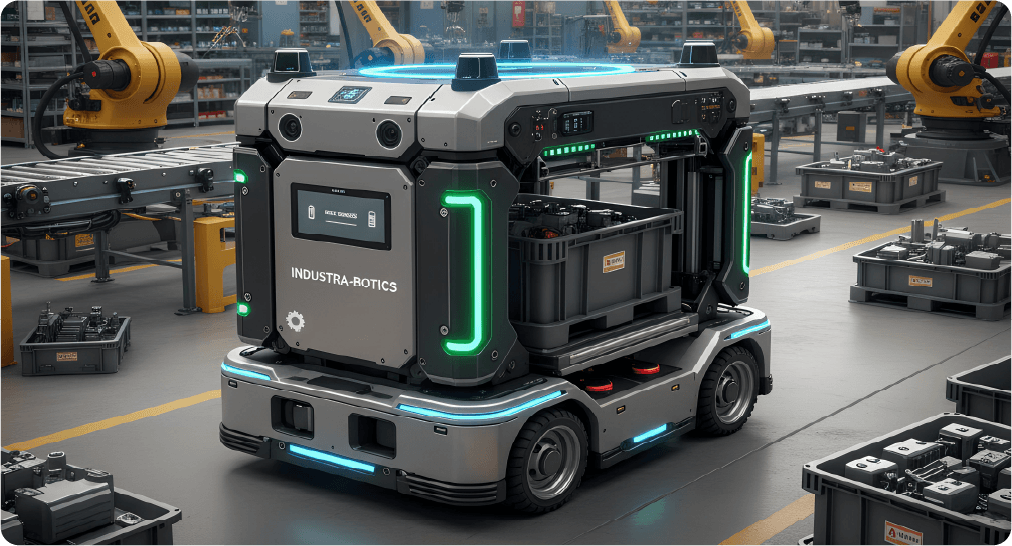

Industrial and Commercial Robots

Robotic systems designed for factories, warehouses, facilities, and industrial environments where reliability, uptime, and safety are critical.

Autonomous Mobile Robots (AMRs)

Engineering autonomous platforms capable of navigation, sensing, and decision‑making in dynamic environments.

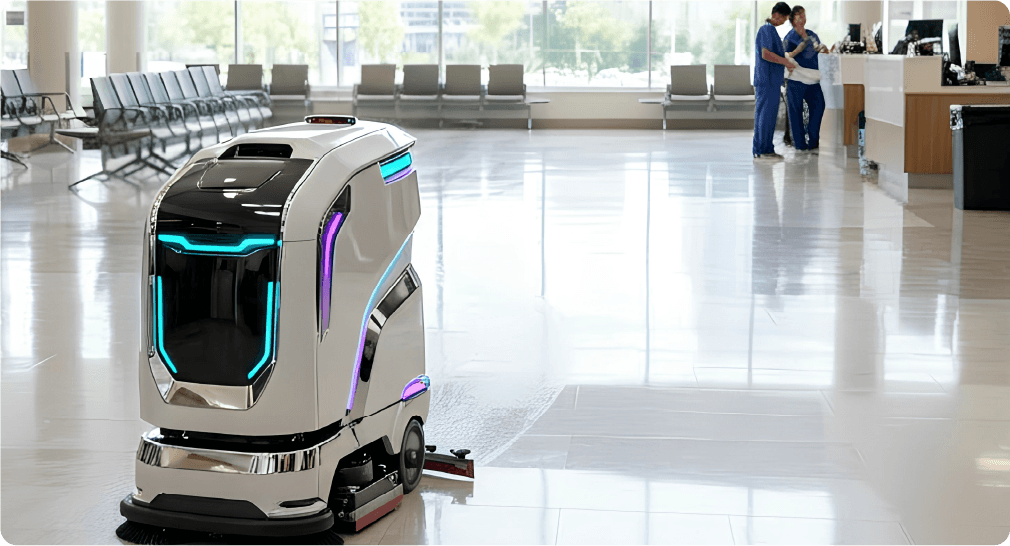

Service Robots

Including automated cleaning, inspection, and facility robots designed to operate safely alongside people.

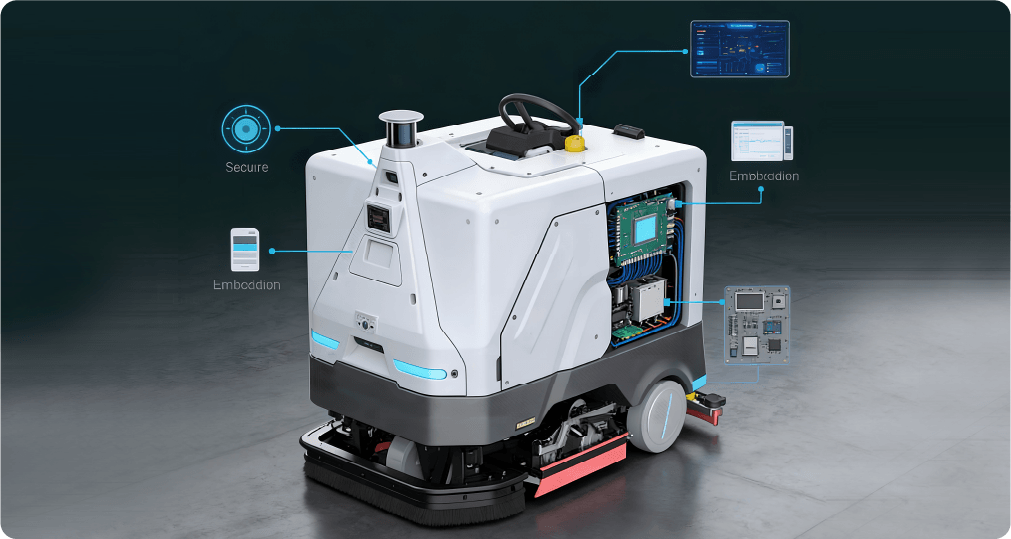

Embedded and Connected Robotic Systems

Robots built around robust electronics, embedded software, and secure connectivity for monitoring, updates, and fleet management.

How We Empower Robotics Companies

Rather than offering isolated services, we help robotics companies reduce risk and accelerate outcomes.

- Faster time‑to‑market through integrated engineering and manufacturing planning

- Reduced technical and compliance risk by addressing safety, reliability, and certification early

- Designs optimized for manufacturing and scale, not just prototypes

- Long‑term product evolution, enabling upgrades, enhancements, and new market entry

This approach allows our clients to focus on market strategy and differentiation while we manage engineering execution.

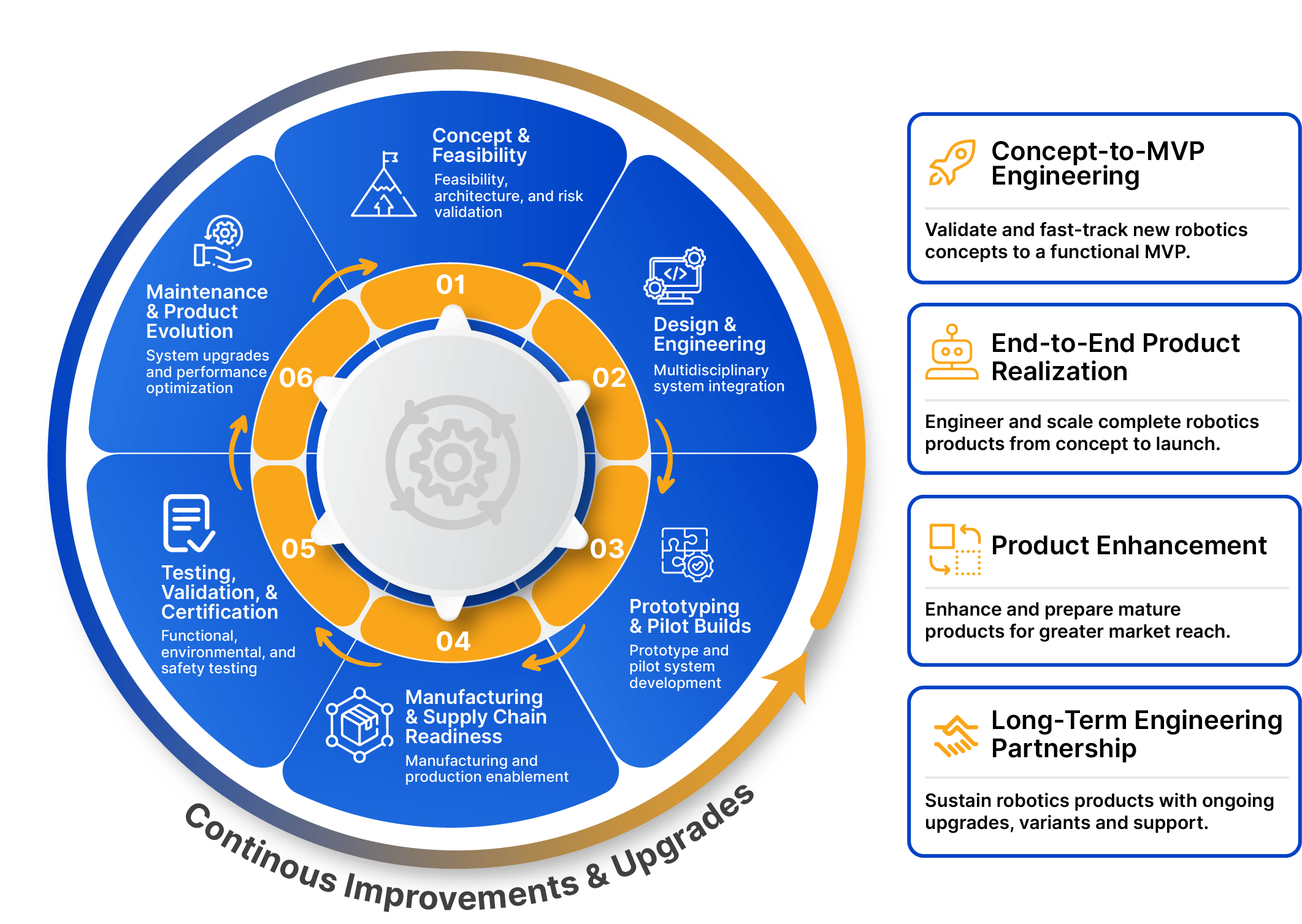

End-to-End Robotics Engineering Lifecycle

We support robotic products across their complete lifecycle, ensuring continuity, accountability, and engineering consistency.

Concept and Feasibility

We help validate ideas through feasibility studies, system architecture definition, and risk assessment, ensuring concepts are technically and commercially viable.

Design and Engineering

This phase integrates multiple disciplines under a unified architecture:

- Industrial and mechanical design

- Electronics design and PCBAs

- Embedded firmware and low‑level software

- Robotics software, control systems, and autonomy

Design decisions are made with manufacturability, reliability, and compliance in mind.

Prototyping and Pilot Builds

We develop functional prototypes and pilot units to validate performance, safety, and real‑world operation before scaling.

Manufacturing and Supply Chain Readiness

From low‑volume builds to scale‑up planning, we support manufacturing processes, vendor coordination, and production documentation.

Testing, Validation, and Certification

Robotic systems are tested against functional, environmental, and safety requirements. We manage certification readiness and execution through internal expertise and trusted partners.

Maintenance and Product Evolution

Post‑launch, we support upgrades, performance improvements, cost optimization, and lifecycle management to keep products competitive.

Enhancing and Scaling Existing Robotic Products

For OEMs and established robotics companies, we enhance and modernize existing platforms without disrupting core operations. Typical engagements include:

Performance and reliability improvements

Every product is built with audit-ready security, regulatory alignment, and enterprise-level controls.

Electronics and firmware upgrades

Every product is built with audit-ready security, regulatory alignment, and enterprise-level controls.

Cost and BOM optimization

Every product is built with audit-ready security, regulatory alignment, and enterprise-level controls.

IoT enablement and fleet connectivity

Every product is built with audit-ready security, regulatory alignment, and enterprise-level controls.

Compliance updates for new regions or applications

Every product is built with audit-ready security, regulatory alignment, and enterprise-level controls.

This allows existing robotic products to remain relevant as technologies and market expectations evolve.

Compliance, Certification, and Market Readiness

Compliance is engineered into our development process—not added at the end. We support:

- Safety and regulatory planning

- Certification documentation and testing coordination

- Alignment with international standards

By combining internal expertise with specialized partners, Powersoft19 acts as a single accountable owner for compliance and certification efforts.

Engineering Robotics for the Future

Robotic products must be designed to evolve. Our engineering philosophy emphasizes:

Modular and upgradeable system architectures

Software‑defined functionality

Data‑driven monitoring and optimization

Secure connectivity for updates and fleet‑level insights

This ensures robotic platforms can adapt to new requirements, technologies, and markets over time.

Why Powersoft19

Clients choose Powersoft19 for our ability to combine deep engineering with practical execution.

Engineering‑led, cross‑disciplinary teams

Experience across robotics, embedded systems, electronics, and manufacturing

Focus on reliability, compliance, and scalability

Global delivery mindset with long‑term partnership approach

Engagement Models

We work with robotics companies through flexible engagement models designed to match different stages of product maturity and organizational needs.

Concept-to-MVP Engineering

Ideal for startups and innovation teams validating new robotic products. We support feasibility, architecture, prototyping, and early compliance planning.

End-to-End Product Realization

For companies building market-ready robotic systems. We take ownership from engineering through manufacturing readiness, certification, and launch support.

Product Enhancement and Scale-Up

Designed for OEMs with existing robots. We improve performance, reliability, cost structure, connectivity, and regulatory readiness.

Long-Term Engineering Partnership

Ongoing support for upgrades, new variants, market expansion, and lifecycle management.

How We Work

Our approach emphasizes clarity, accountability, and engineering discipline.

Discovery and Alignment

We understand product goals, constraints, and market requirements.

Validation and Readiness

Testing, certification planning, and manufacturing alignment.

Launch and Evolution

Post-launch support, optimization, and continuous improvement.

System Architecture and Planning

We define scalable, compliant system architectures.

Cross-Disciplinary Engineering

Mechanical, electronics, embedded, and software teams work in parallel.

This structured process reduces risk while maintaining flexibility as products evolve.

Let’s Build or Enhance Your Robotic System

Whether you are developing a new robotic concept or enhancing an existing product, Powersoft19 can support your journey from engineering to market readiness. Talk to us about:

- Robotics product development

- Autonomous systems engineering

- Product enhancement and scale‑up

- Certification and compliance planning

Start with:

- Robotics Discovery Call – Discuss your concept, challenges, or enhancement goals with our engineering team.

- Robotic Product Audit – A structured technical review of your existing robot covering performance, electronics, software, manufacturability, and compliance readiness.

We help you move forward with clarity, confidence, and engineering depth.